Discover Leading Semiconductor Test Innovators

Top 5 Semiconductor Test Companies of 2024

Explore the forefront of semiconductor testing with our curated list of industry leaders, renowned for their cutting-edge technology and exceptional service.

Importance of Semiconductor Testing

In the semiconductor industry, ensuring the quality and reliability of semiconductor devices is paramount. Semiconductor testing plays a crucial role in this process, involving a series of rigorous tests and inspections to verify that devices meet the required specifications and performance standards.

Electron Test Equipment CEO, Mr. Edward Herniak, stated that “Semiconductor testing cannot be overstated, as it directly impacts the functionality, safety, and overall quality of the final product.”

Through comprehensive semiconductor testing, manufacturers can identify and eliminate faulty or defective chips, significantly reducing the risk of device failure. This meticulous process ensures that only reliable and high-quality semiconductor components are used in various applications, from consumer electronics to industrial systems.

By delivering dependable products, companies foster trust and build long-term relationships with clients, ultimately driving business success in the competitive semiconductor industry.

Leading Semiconductor Testing Companies

Electron Test Equipment

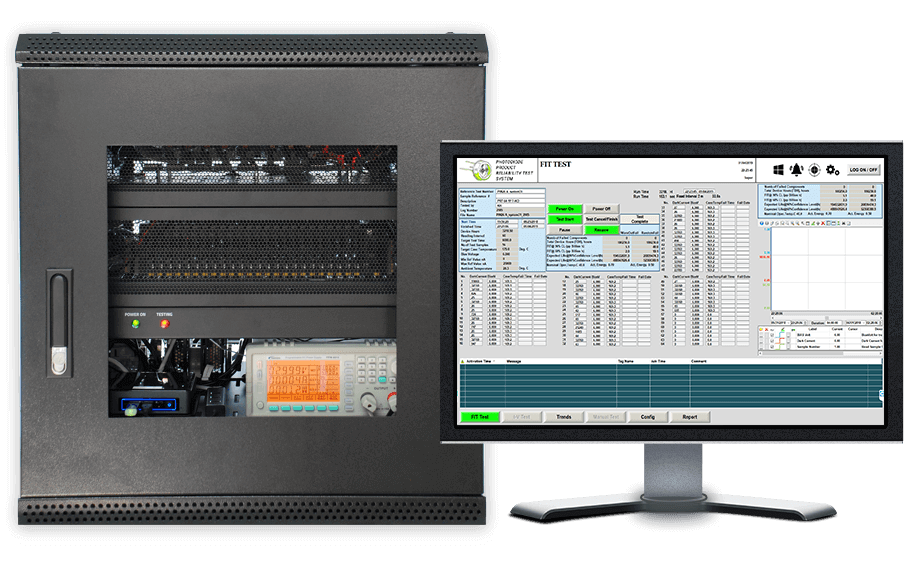

Provides custom-made semiconductor testing and photodiode reliability equipment. ElectronTest.com offers automated test equipment to enhance the efficiency and accuracy of semiconductor testing processes. Their equipment is widely recognized for its reliability and performance in both R&D and production environments.

They handle large government projects around the world.

Advantest Corporation

A leading provider of semiconductor test solutions, Advantest is renowned for its innovative ATE systems that cater to a variety of applications, including high-speed digital, analog, and mixed-signal devices. Advantest plays a crucial role in protecting valuable intellectual property through litigation support for companies dealing with potential threats or patent infringement challenges.

Teradyne

They make automatic test equipment but often they have difficulty with custom made projects. Teradyne specializes in testing systems for a wide array of semiconductor devices. Their solutions are designed to improve testing efficiency while reducing costs, making them a preferred choice for manufacturers worldwide.

.

ATEC Group

They are a prominent provider of semiconductor testing services, offering a wide range of ATE solutions tailored to meet the needs of semiconductor manufacturers. Their expertise spans various testing environments, including reliability testing and validation services

.

Secure Your Competitive Edge

Take the first step towards optimizing your semiconductor testing process. Our engineers will evaluate your needs and send you a customized quote.

Types of Semiconductor Devices

Semiconductor devices encompass a wide range of electronic components that are integral to numerous applications, from consumer electronics to automotive and industrial systems. Here are some common types of semiconductor devices:

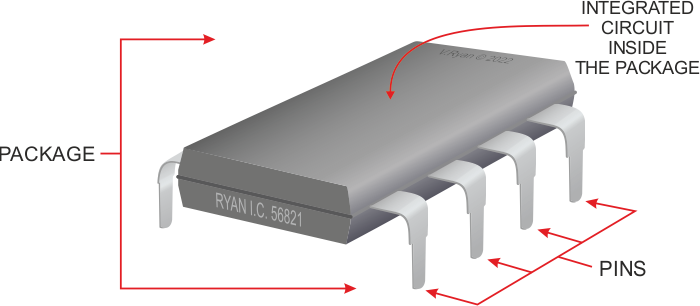

- Integrated Circuits (ICs): These are complex electronic circuits fabricated on a single piece of semiconductor material, typically silicon. ICs are the building blocks of modern electronic devices, enabling compact and efficient designs.

- Microprocessors: A type of IC that contains the central processing unit (CPU) of a computer or other electronic device. Microprocessors are essential for executing instructions and performing calculations in various digital systems.

- Memory Devices: These semiconductor devices store data, such as random-access memory (RAM) and read-only memory (ROM). Memory devices are crucial for data storage and retrieval in computers and other electronic devices.

- Power Management Devices: These components regulate and manage power in electronic systems, including voltage regulators and power amplifiers. Power management devices ensure efficient energy use and stable operation of electronic circuits.

- Wireless Devices: Semiconductor devices that enable wireless communication, such as radio frequency (RF) transceivers and antennas. Wireless devices are fundamental to modern communication systems, including smartphones and IoT devices.

By understanding the diverse types of semiconductor devices, manufacturers can tailor their testing processes to meet the specific requirements of each component, ensuring optimal performance and reliability.

Scalable Test Architecture

A scalable test architecture is a cornerstone of effective semiconductor testing strategies. It refers to the ability of a test system to adapt to evolving test requirements and to scale up or down to accommodate different devices and applications. This flexibility is essential for addressing the diverse and dynamic nature of the semiconductor industry.

Key features of a scalable test architecture include:

Modular Design: This allows test systems to be easily configured and reconfigured to meet changing test requirements. Modular design enhances flexibility and enables efficient use of resources.

Electron Test Equipment has modular designs so you can expand the number of test units without having to buy a whole new system.

-

Automatic Test Equipment (ATE): Specialized equipment designed to automate the testing process, reducing the need for manual intervention and increasing test efficiency. ATE systems are crucial for handling high volumes of semiconductor devices with precision and speed.

-

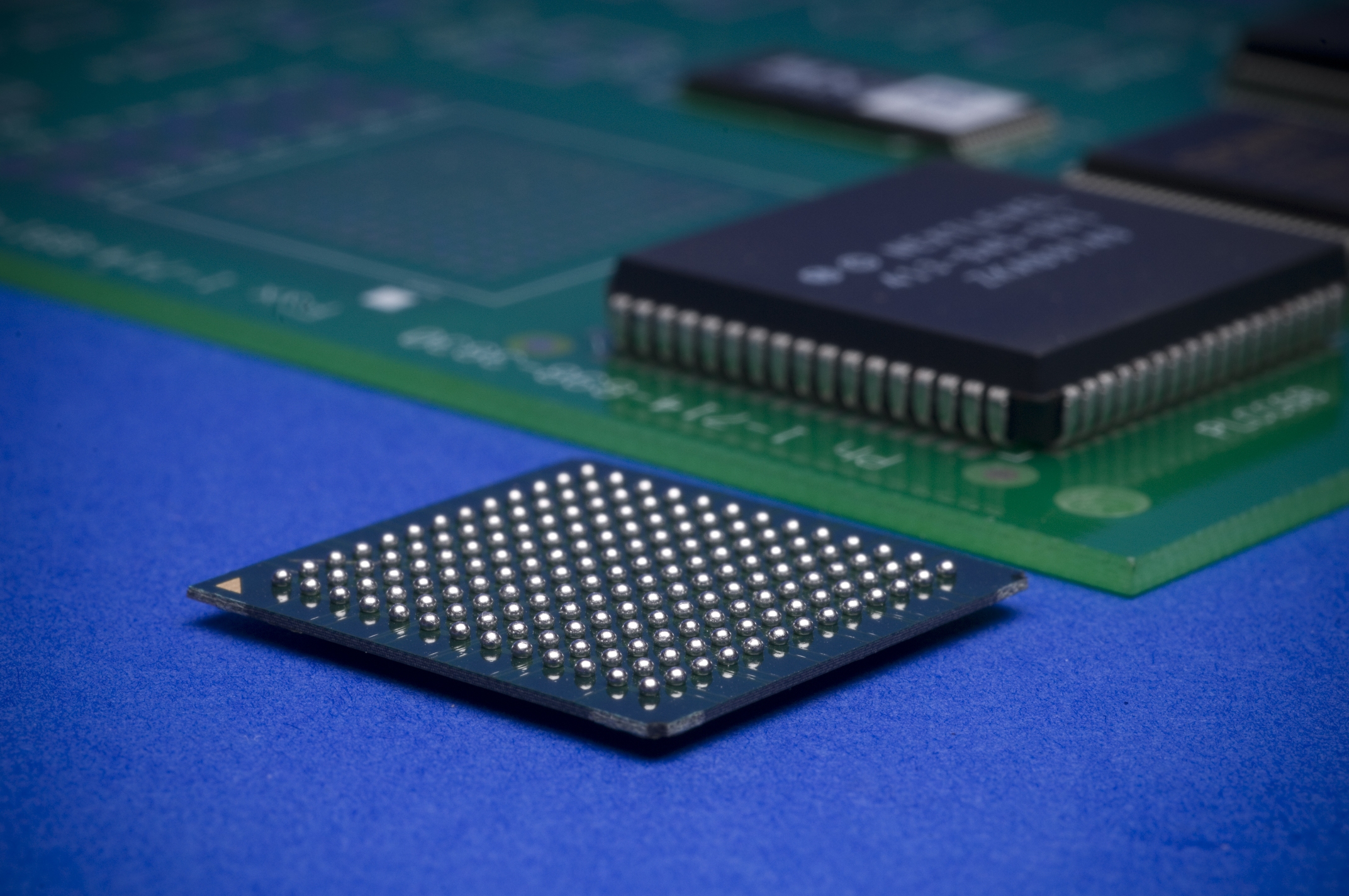

Advanced Semiconductor Packaging: The use of advanced packaging technologies, such as flip-chip and wafer-level packaging, enables the testing of complex semiconductor devices. These packaging methods support high-density integration and improve thermal performance.

-

Failure Analysis: The process of identifying and analyzing failures in semiconductor devices to improve yield and reduce the risk of device failure. Failure analysis provides valuable insights for enhancing design and manufacturing processes.

By incorporating these features, a scalable test architecture ensures that semiconductor devices are thoroughly tested and validated. This approach minimizes the risk of device failure and guarantees that only high-quality devices are delivered to customers, maintaining the integrity and reputation of semiconductor manufacturers.