Trusted by Semiconductor Manufacturers & Government Institutions

Versatile Automated Testing

Our custom automatic test equipment is designed for versatility, enabling testing across multiple component packages and testing chambers.

Cost-Effective

Our cost-effective electronic test equipment delivers scalable solutions that ensure high-quality performance and reliability while optimizing your testing budget.

Exceptional Support

We provide exceptional support through commissioning and training. We also help engineering teams with automatic test equipment and semiconductor testing solutions.

Automatic Test Equipment Solutions for Critical Operations & High Stakes Applications

As a trusted partner to semiconductor manufacturers and government institutions, we specialize in manufacturing custom Automated Test Equipment (ATE) designed to rigorously assess electronic devices and ensure their reliability in mission-critical applications.

Increase semiconductor product reliability through accurate and cost-effective semiconductor test equipment that automatically tests, measures, and controls up to 1024 semiconductor devices simultaneously in various environmental conditions.

Our ATE test systems are specifically designed to enable efficient testing, ensuring seamless performance, high throughput, and consistent quality.

These systems play a crucial role in production testing, where speed and precision are essential for meeting high-volume manufacturing demands without compromising on reliability. By automating the testing process, manufacturers can reduce test time, minimize errors, and optimize their production workflows.

Custom Test Fixtures & Boards

We design and manufacture specialized DUT boards, fixtures, and jigs tailored to your packaged semiconductor and device testing requirements, enhancing accuracy and efficiency.

Burn-in Testing

Burn-in testing for electronic components to elevated stress conditions, such as increased temperatures and voltages, to identify and eliminate early-life failures, ensuring only reliable components proceed to deployment.

Environmental Stress Testing

Our ATE test systems can be equipped to subject devices to various environmental conditions (temperature, humidity, vibration) to assess performance and durability for mission-critical applications.

Reliability & Life Testing

Our automatic test equipment eliminates manual testing time and simultaneously conducts accelerated life tests to predict device longevity and identify potential failure modes.

Functional Testing

Our custom ATE test evaluates the overall functionality of electronic devices, ensuring they perform as expected under a variety of conditions.

Software & Reporting

Easy-to-use software interface for real-time test results, configuration, and 3rd party data reporting tools.

Advanced ATE Solutions Engineered for Your Industry

Aerospace / Defense

Automated Test Equipment for Defense & Aerospace

Our ATE systems rigorously test semiconductor components in avionics, radar, and guidance systems to ensure they meet stringent safety and performance standards – guaranteeing mission objectives.

Telecommunication

Automated Test Equipment for Telecommunication

Our ATE systems test semiconductors used in communication devices, network infrastructure, and signal processing, ensuring high performance and reliability in modern connectivity solutions.

Medical / Health

Automated Test Equipment for Medical / Health

Our ATE systems validate semiconductors in medical devices, diagnostics, and monitoring equipment, ensuring accuracy, safety, and adherence to healthcare standards.

Automotive

Automated Test Equipment for Automotive

Our ATE systems rigorously test semiconductors in vehicle control systems, sensors, and infotainment modules, ensuring reliability, safety, and optimal performance.

Research & Development

Automated Test Equipment for Research & Development

Our ATE systems support testing of semiconductors used in experimental designs, advanced sensors, and computing prototypes, fostering innovation with precise and reliable results.

Security & Surveillance

Automated Test Equipment for Security & Surveillance

Our ATE systems test semiconductors used in surveillance equipment, encryption devices, and detection systems, ensuring durability, accuracy, and operational security.

Custom ATE Examples

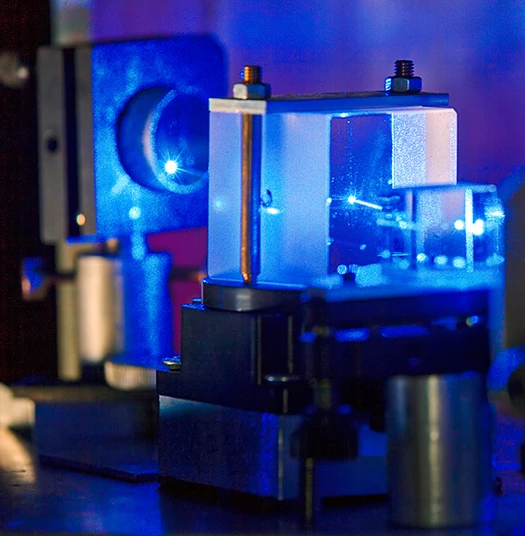

Automatic Test Equipment for the Optoelectronic Industry

One example of the custom Automated Test Equipment (ATE) we manufacture serves the optoelectronic industry. Our custom ATE-Laser Test Systems and ATE-Photodiode Test Systems provide precise testing and measurement control for over 64 laser diodes (Continuous Current) or photodiode components. These systems utilize various test instruments to perform and evaluate critical parameters of these devices with high accuracy.

Designed to meet the rigorous reliability standards of military and telecom industries, the systems excel in testing under extreme conditions. This includes sub-zero thermal shock (as low as -40°C), high humidity (20% to 95% RH), and elevated temperatures (up to 175°C) for burn-in, accelerated aging, and product characterization. These features ensure robust and reliable performance for critical applications.

Automatic Test Equipment for Telecom

Automated testing is crucial in the telecom industry, particularly for photodiodes used in telecommunication devices. These components are vital for the transmission and reception of optical signals in fiber optic communication systems, which form the backbone of modern telecommunications.

We significantly enhanced photodiode reliability testing for QSFP28 transceivers by developing and delivering custom Automated Test Equipment (ATE). Our solution addressed critical challenges, including a tight budget, accelerated timelines, and the need to meet the stringent Telcordia GR-486 standards.

The ATE, designed for 256 channels and customized with user-friendly software, was delivered within six weeks and included features such as I-V sweep and FIT testing to ensure the photodiodes met reliability benchmarks.

This system facilitated precise data analysis, including failure rate predictions through accelerated life testing, enabling the client to transition to mass production confidently.

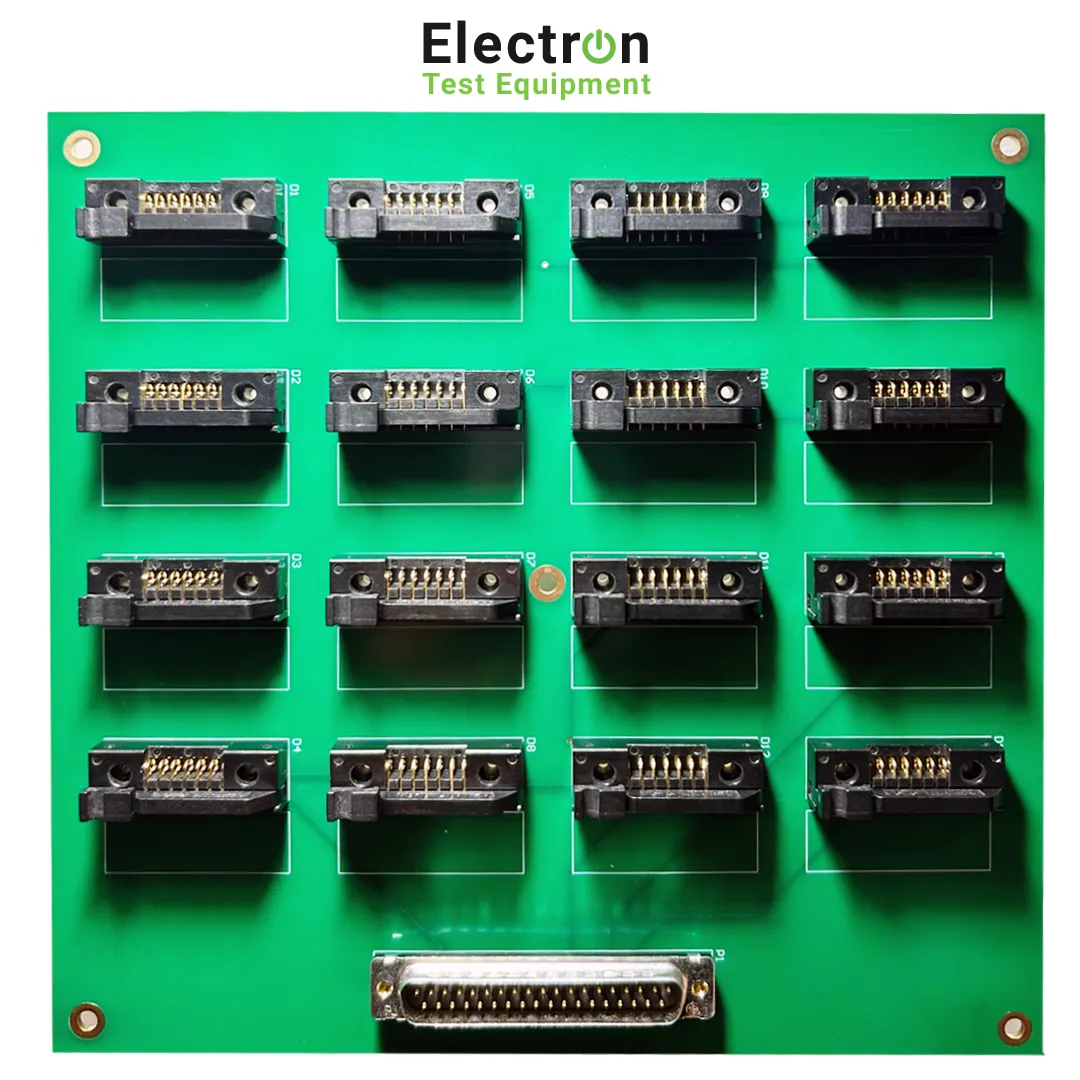

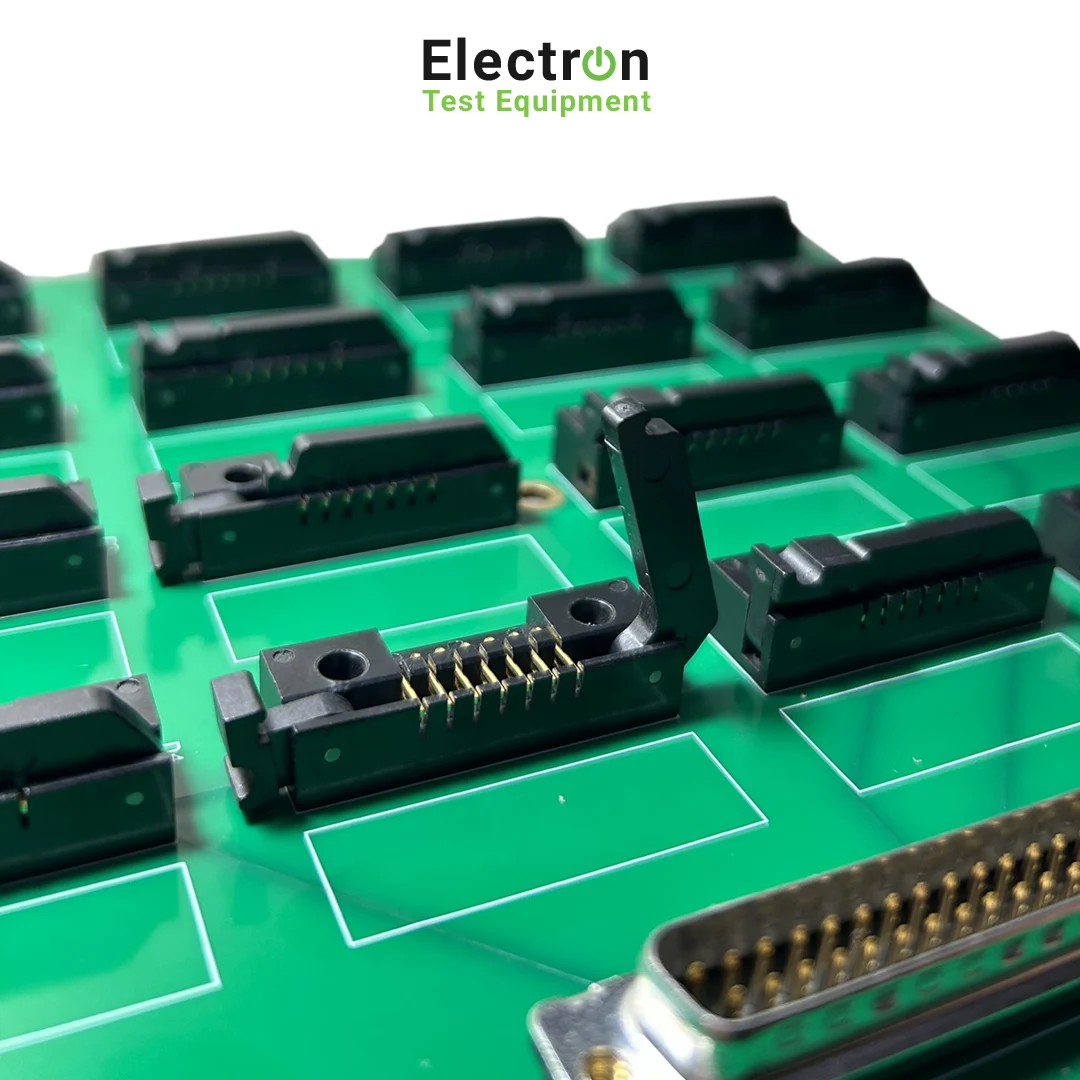

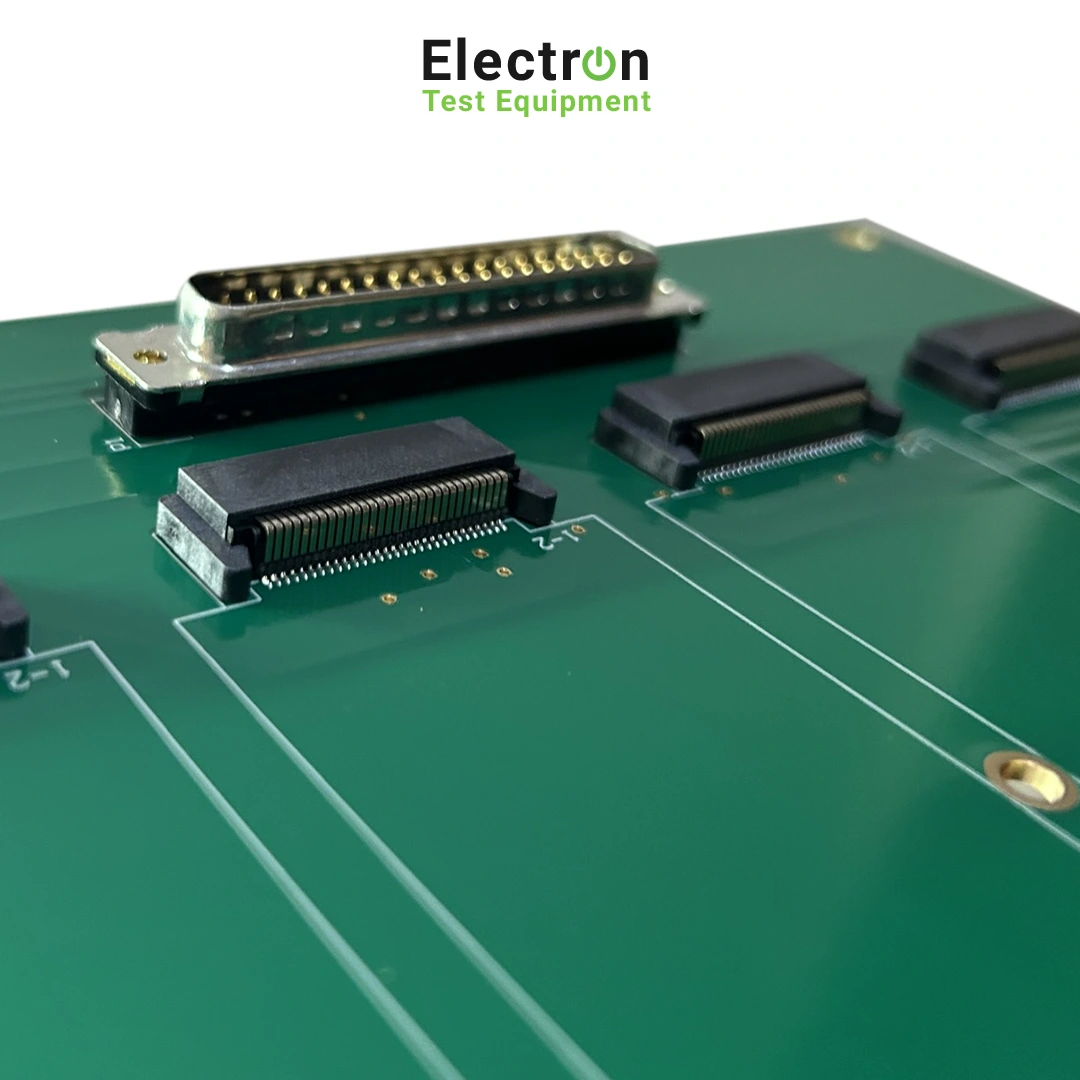

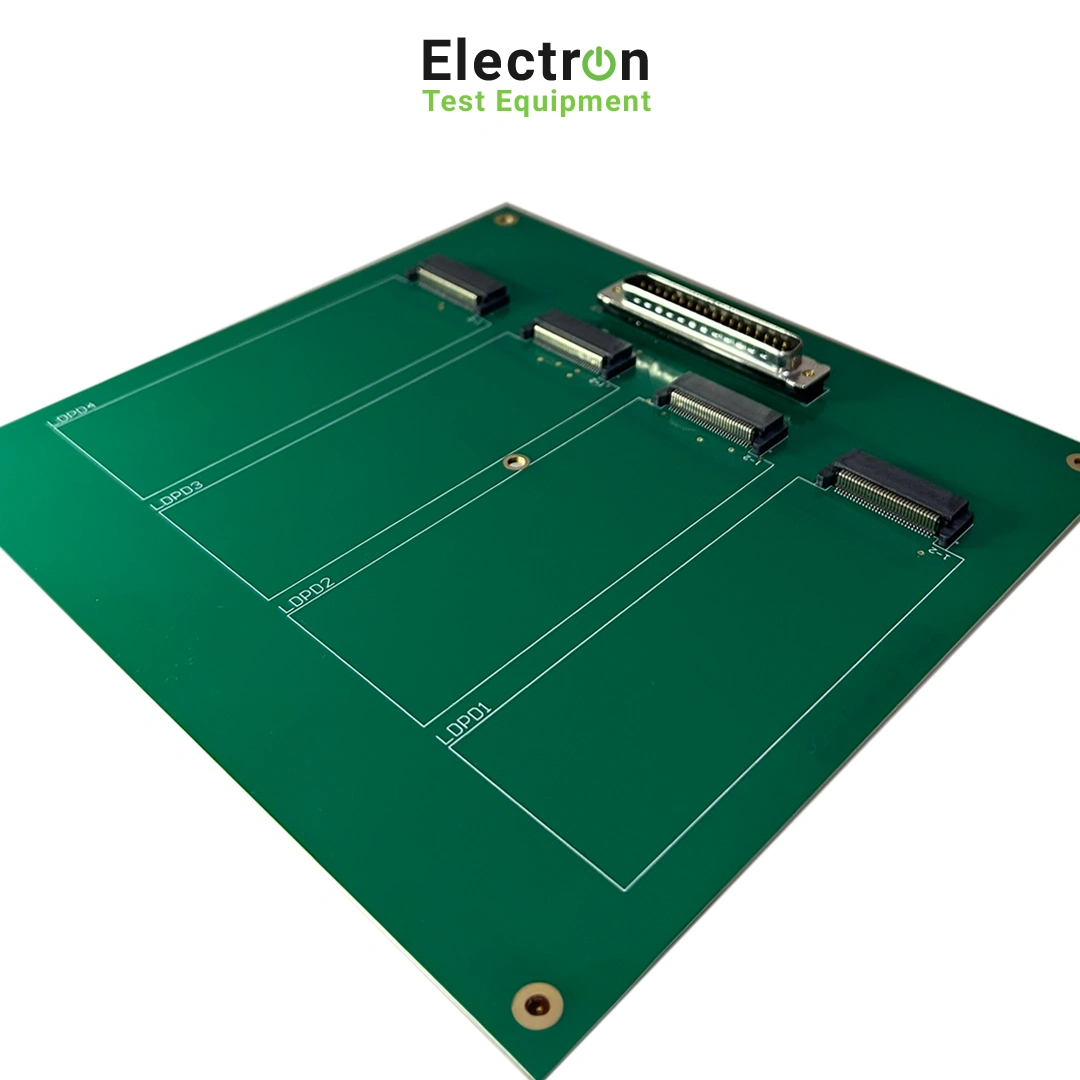

Custom DUT Boards

In our ATE (Automated Test Equipment) designed for laser diode test systems and photodiode test systems, we eliminated the need for traditional test probes by leveraging DUT (Device Under Test) boards.

These boards are designed to securely hold the component in place while providing all necessary electrical connections. Once the component is inserted into the interface board, the measurement process is carried out through a direct connection via a cable, ensuring accurate and consistent readings without the complexity and potential instability of a probe.

This setup also minimizes handling errors, improves test repeatability, and reduces wear on the component or testing equipment.

Our custom DUT (Device Under Test) boards are capable of measuring key parameters of laser diodes and photodiodes, with results displayed seamlessly in our software, including:

- Wear-out: Testing the device under prolonged exposure to operating and environmental stresses to evaluate durability and reliability.

- Mean Time Between Failures (MTBF): Measuring the average operational time before semiconductor breakdowns occur.

- LIV Curve for lasers and IV Curve for photodiodes: Generating characteristic curves to analyze performance under varying current and voltage.

- Dark Current: Assessing the current that flows through the photodiode in the absence of light to measure noise and leakage performance.

- This ensures comprehensive and accurate testing of critical parameters for high-performance applications.

Learning Center & FAQ

Overview of Automated Test Systems

An automated test system (ATS) is a sophisticated, computer-controlled setup that utilizes a combination of software and hardware tools to execute pre-scripted tests on electronic devices. An ATS typically comprises several critical components:

- Test Instruments: These include oscilloscopes, signal generators, and power supplies, which are essential for conducting precise measurements and tests.

- Data Acquisition Systems: These systems are used to collect and analyze test data, ensuring accurate and comprehensive data acquisition.

- Instrument Control Software: This software is responsible for controlling the test instruments and executing the test scripts, providing seamless instrument control.

- Test Software: This is used to develop and execute the test scripts, ensuring that the tests are conducted according to the predefined requirements.

Automated test systems are widely utilized across various industries, including the semiconductor industry, automotive industry, and aerospace industry. They play a crucial role in testing electronic devices to ensure they meet the required specifications and standards. By leveraging the capabilities of ATS, companies can achieve more efficient, accurate, and cost-effective testing processes, ultimately enhancing the reliability and performance of their electronic systems.

Whether your semiconductor is an electronic assembly or semiconductor – we can test any electronic device for product reliability.

We offer additional support to help your engineers to design for reliability. Automated test equipment (ATE) offers significant advantages over manual testing methods by streamlining testing processes, improving accuracy, consistency, and speed, and reducing human intervention.

We can help model MTBF (Meantime Between Failure) and MTTF calculations to determine the product reliability for a specific period of time. Automated testing also streamlines the testing process, making it faster, more accurate, and more consistent.

Be sure your semiconductor will last.

Custom ATE

Quote Request

Need a custom automated Test Equipment solution?

Submit your requirements and our application engineers will create a custom solution.

HEAD OFFICE

Electron Test Equipment Limited

5a Whytecliffe Road South,

Purley, CR8 2AY, England

Phone: + 44 1293 904 001

E-mail:

moc.tsetnortcele@ofni