LIV Test System for Laser Diodes

The light-current-voltage (LIV) sweep test is a fundamental measurement to determine the operating characteristics of a laser diode.

Our LIV Test System is designed for applications

that require the highest measurement accuracy and testing of up to 1024 devices at the same time.

Combined Source & Measurement

The versatile LIV Test System combines source and measurement devices into one system. The LIV Test System is a compact and cost-effective Source/Measure Unit (SMU) with the capability to output and measure both voltage and current of 64 to 1024 laser diode devices. The LIV Test System provides the capability to assess the laser characteristics of all devices across all four measurement quadrants without the need for additional equipment.

Source Voltage

Source Current

Meter Voltage

Meter Current

LIV Laser Test System Specifications

| Reliability Test | LIV Results |

| Measured Quantities | LIV Curve |

| Number Test Components | 64 – 1024 |

| Voltage Accuracy (Measured) | 0.1% + -15mV |

| Current Range | 1mA – 5,000 mA |

| Current Accuracy (Measured) | 0.1% of Full Scale |

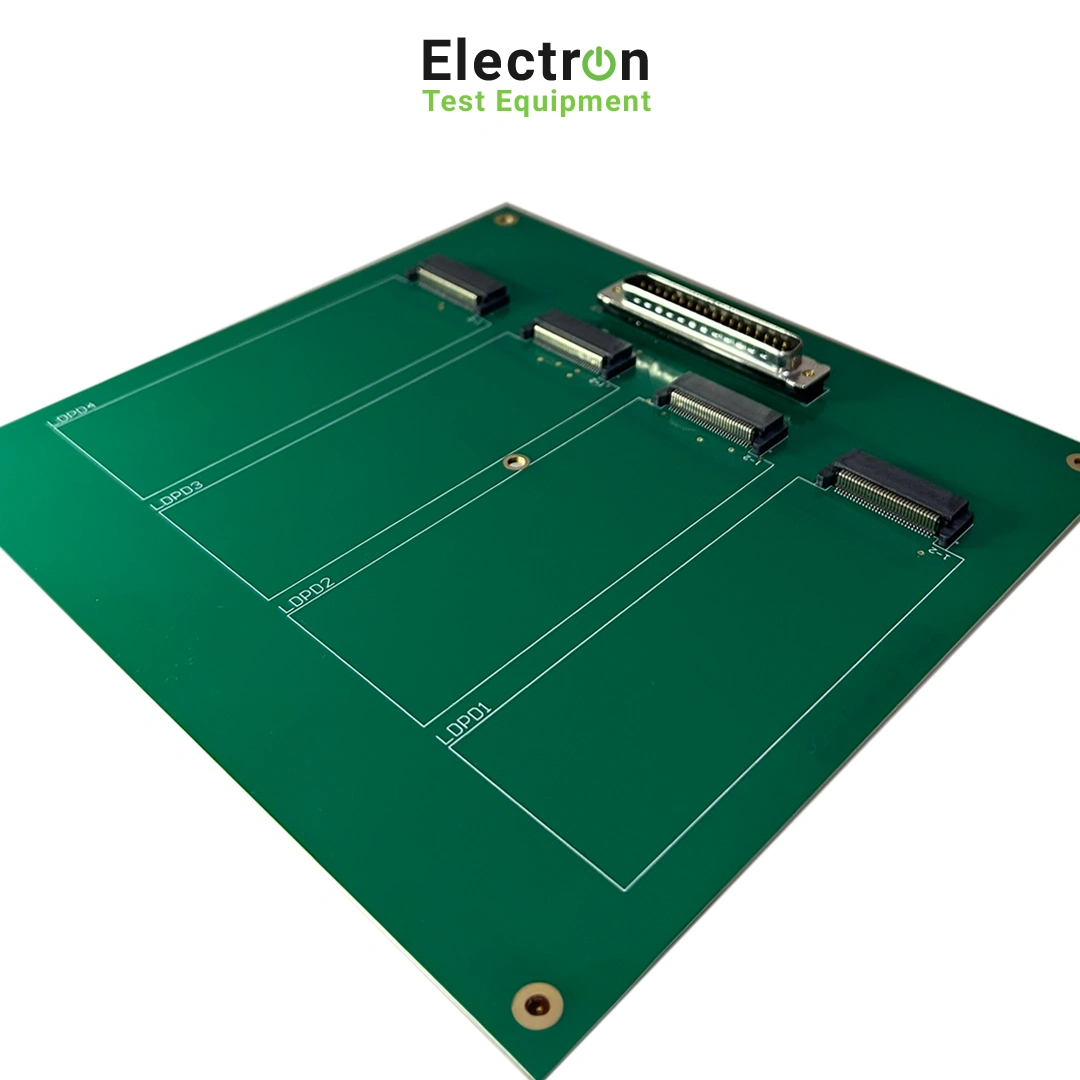

| Source Measure Board | Custom Interface Test Fixture |

| Voltage Programming Resolution | 0.1 V to 5 V, 64 steps |

| Maximum Current | 5,000mA |

| Default Current Measurement Resolution | Analog to Digital 13 bit |

| Scan Time | 2 to 6 seconds |

| Input Voltage | 110V – 240V AC |

| Power Consumption | 220 Watts |

| System Dimensions (mm) | L-515 x W-477 x H-395 (size based on 64 component testing) |

| Material: | Aluminum/Steel |

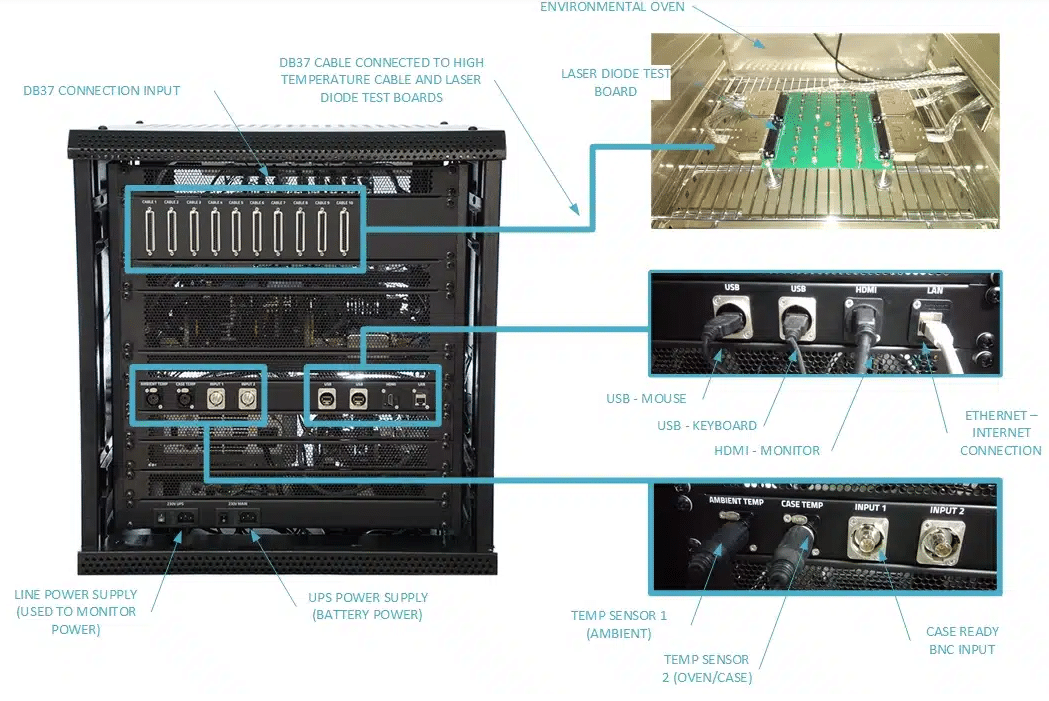

How The LIV Test System Works

Semiconductor diodes are placed in an environmental chamber at a set temperature and current and is applied to the laser diodes at interval steps (LIV test sweep) and the intensity of the resulting emitted light and voltage is measured.

The final laser diode LIV test results are displayed onto a graph which is known as an “LIV curve”. The following characterization can be determined based on the LIV measurement: Power vs. current ; Power vs. voltage ; Threshold current ; Series resistance ; Slope efficiency.

LIV Test System Features

The custom LIV Test System comes with various hardware configurations and is customizable for various LIV test conditions for your laser diode.

Standard Features include:

- Test 64 to 1024 laser diodes

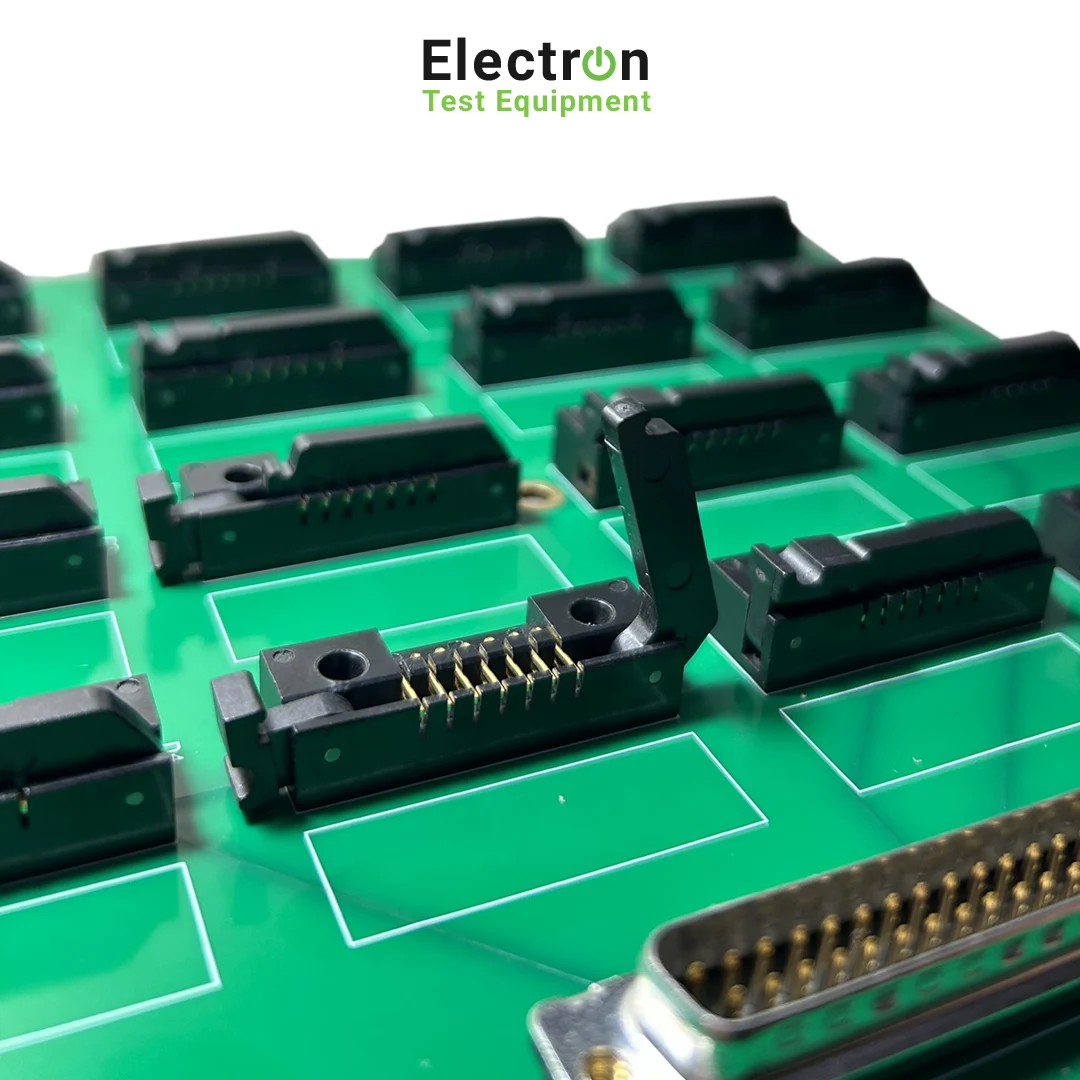

- Easily switch DUT (device under test) boards from TO-Can to Butterfly package

- Power Monitoring & UPS Backup

- Ethernet Communication

- Custom Input & Output Interface Connectors

- Custom interface control with third-party environmental chambers

- An easy to use GUI software provides real-time testing and functional reports

Test Standards

With advanced software test configurations, you can customize settings that meet various organization test standards such as the Telcordia (Bellcore) GR-468-CORE, MIL-STD-883E, and Test Method 1016.

Packaged IC

For packaged ICs, we manufacture a custom interface fixture for packaged lasers to ensure proper connectivity and test reliability.

Software Support

Our dedicated support staff provides outstanding training and will help your team configure the software for your application.

Depending on your requirements, the software can be customized to meet your semiconductor test requirements. When you choose an Electron Test Equipment product you not only get the most advanced semiconductor test equipment – you receive outstanding support and service.

Designed to Work With All Environmental Test Chambers

The LIV Test System works with all environmental test chambers for various environmental conditions for your laser diode.

Resources

Laser Diode Datasheets, Case Studies, & Brochure

To access, please provide your:

The light current and voltage are key factors in determining the optical output power of a laser diode. A significant voltage drop can negatively affect the output power and reduce the overall optical output efficiency.

Our laser diode testing systems come with advanced software test configurations. You can customize settings that meet various organization test standards such as the Telcordia (Bellcore) GR-468-CORE, MIL-STD-883E, and Test Method 1016.

Reliability laser diode testing plays a critical role in ensuring the performance and longevity of laser diodes used in various applications. A comprehensive test system is used for optically tested diodes, where burn in testing and life tests are conducted to simulate long-term usage and stress. Through batch testing, manufacturers can identify any weaknesses in production runs, while qualification testing ensures that each laser diode meets the necessary standards for reliability. A robust reliability test system is essential for consistent reliability testing, offering accurate data that helps predict the expected lifespan and operational stability of each diode.

During laser diode qualification, key factors such as output power, voltage drop, and near field performance are evaluated to ensure high power operation and reliability. Accelerated aging is a cost-effective method to test laser diodes, verifying their durability while maintaining optimal optical power and ensuring they are optically tested for maximum efficiency. Semiconductor diodes are placed in an environmental chamber at a set temperature and current and is applied to the laser diodes at interval steps (LIV test sweep) and the intensity of the resulting emitted light and voltage is measured. The final laser diode LIV test results are displayed onto a graph which is known as an “LIV curve”. The following characterization can be determined based on the LIV measurement: Power vs. current ; Power vs. voltage ; Threshold current ; Series resistance ; Slope efficiency. With the rapid advancements in the electronics industry, reliability is a concern in every laser diode testing application. Laser diode life testing or accelerated aging is extremely important as part of qualification during product development as well as for batch testing throughout the production life of the laser. Also, high-temperature burn-in tests are used in laser diode manufacturing to filter out components prone to premature failure and ensure the remaining lot of laser diodes will meet the acceptable level of reliability based on the test standard used. Testing also ensures the diode delivers consistent output power under varying conditions. This qualification process is essential for achieving reliable laser performance while maintaining a low cost for high-volume production. By analyzing the resulting LIV curve, engineers can assess key characteristics like slope efficiency, which indicates how efficiently the diode converts electrical input into light. Proper testing also helps identify any issues with the diode element, reducing the risk of failures like catastrophic optical damage that could compromise the system's performance. Burn-in testing is often conducted to simulate real-world conditions and confirm the mean time to failure, ensuring long-term reliability. No, all semiconductors need to be packaged in order to mount them to the customer DUT (device under test) boards. Our dedicated support staff provides outstanding training and will help your team configure the software for your laser diode testing application. Depending on your requirements, the software can be customized to meet your semiconductor test requirements. When you choose an Electron Test Equipment product you not only get the most advanced semiconductor test equipment – you receive outstanding support and service.How does the RPT-LASER Works?

How Does The LIV Test System Works?

Why Use Accelerated Lifetime Testing & Burn-in for Laser Diodes?

How is Laser Diode Qualification Performed?

What is the Importance of Laser Diode Testing?

Does your equipment work with unpackaged components?

How does Electron Test Equipment provide training & support?

LIV Laser Diode Test System

Quote Request

Need a custom laser diode reliability & burn-in test solution? Submit your requirements, and our application engineers will create a custom solution.

HEAD OFFICE

Electron Test Equipment Limited

5a Whytecliffe Road South, Purley, CR8 2AY, England

Phone: + 44 1293 904 001

E-mail:

moc.tsetnortcele@su-tcatnoc