Trusted by Semiconductor Manufacturers & Government Institutions

Versatile Laser Diode Testing

Our laser diode test systems are designed for versatility, enabling testing across multiple component packages and environmental chambers.

Cost-Effective

Our cost-effective laser reliability test systems delivers scalable solutions that ensure high-quality performance and reliability while optimizing your testing budget.

Engineering Support

Our team provides exceptional support from design to comissioning. We help engineering teams with automatic test equipment & semiconductor testing solutions.

Specification

| Reliability Test | FIT (Failure In Time), MTTF (Mean Time to Failure) |

| Measured Quantities | LIV Curve, Threshold Current, Operating Current, Forward Voltage, Monitoring Current, Vmax, Imax, Imin |

| Number Test Components | 64 - 1024 |

| Current Range | 1 mA – 5,000 mA |

| Current Accuracy (Measured) | 0.1% of Full Scale |

| Source Measure Board | Custom Device Under Test Board |

| Current Sweep | 0.1 mA to 200 mA (200 steps) |

| Maximum Current | 5,000mA |

| Default Current Measurement Resolution | Analog to Digital 13 bit |

| Scan Time | 2 to 6 seconds |

| Input Voltage | 110V - 240V AC |

| Power Consumption | 220 Watts |

| System Dimensions (mm) | L-515 x W-477 x H-395 (size based on 64 component testing) |

| Material: | Aluminum/Steel |

| Conforms to Test Standards | Telcordia (Bellcore) GR-468-CORE MIL-STD-883E, Test Method 1016 |

| Types of Testing | Accelerated aging, burn-in, and qualification testing |

| Chamber Compatibility | Designed to work with environmental test chambers: HAST, HTOL, Autoclave, Temperature & Humidity, Bias Test |

| Power Monitoring & UPS Backup | Power failure mode ensures data integrity even through power blackouts |

| Current Accuracy (Measured) | 0.1% of Full Scale |

| Laser Diode Protection | Custom current high/low limits are set to protect the laser from damage during burn-in or reliability testing |

| Automatic Constant Current | In ACC mode the laser diode’s output power is held constant by continuously adjusting current as required to maintain constant output power. The system Optical output power is measured by using an internal monitor photodiode if one is available within the laser. |

| Light Current Voltage (L-I-V) | By applying increasing current to the laser diode so it that emits light, the optical output is measured together with the voltage drop across the diode element. The resulting LIV curve reveals important clues about the quality of manufacture and the performance of the laser diode. |

| Automatic Power Control | In APC mode, the system monitors the optical output and provides a control signal for the laser diode which maintains the operation at a constant optical output level. Optical output power is measured either with an external or photodiode within the laser. |

Laser Diode Burn-in & Reliability Testing

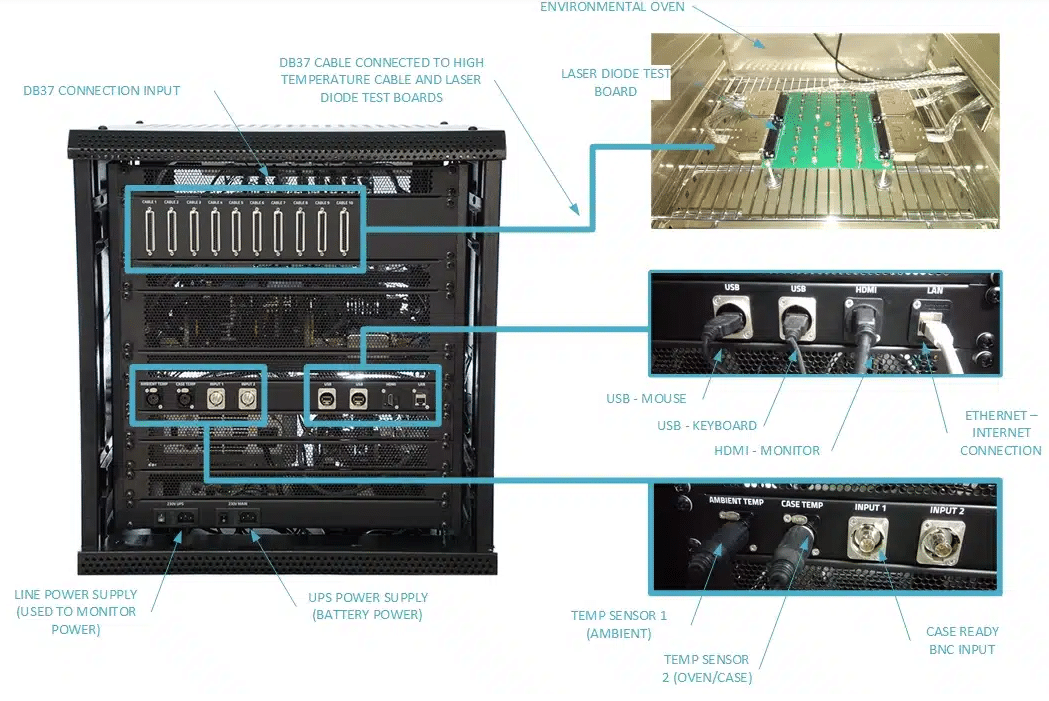

The PRT-LASER provides low-cost, high-performance accelerated aging, burn-in testing, and qualification testing for laser diode reliability. It uses precise control, allowing the user to test up to 1024 laser diodes with various environmental chambers.

LIV Testing for Laser Diodes

The PRT-LASER provides light-current-voltage (LIV) sweep testing, which is a fundamental measurement to determine the operating characteristics of a laser diode. The LIV Test System is designed for applications that require the highest measurement accuracy and testing of up to 1024 devices at the same time.

Temperature Control and Adjustment

The PRT-LASER system has the capability to control and adjust the temperature of the laser diodes. This feature is essential for simulating various operating conditions and ensuring the diodes can perform reliably under different thermal environments.

Burn-in Testing for Laser Diodes

The PRT-LASER system can perform burn-in testing to accelerate the aging process of the laser diodes. This helps identify any potential failures early and ensures the long-term reliability of the diodes.

Catastrophic optical damage can occur in a laser’s optical system if the optical output exceeds the threshold, making laser diode qualification essential.

Optical Power Monitoring

The PRT-LASER can be equipped to measure the optical output power using a photodiode, which is crucial to ensure reliable performance.

High power diodes are crucial in applications such as laser systems and telecommunications, where they must reliably handle large amounts of electrical current without failure.

Laser Package Compatibility

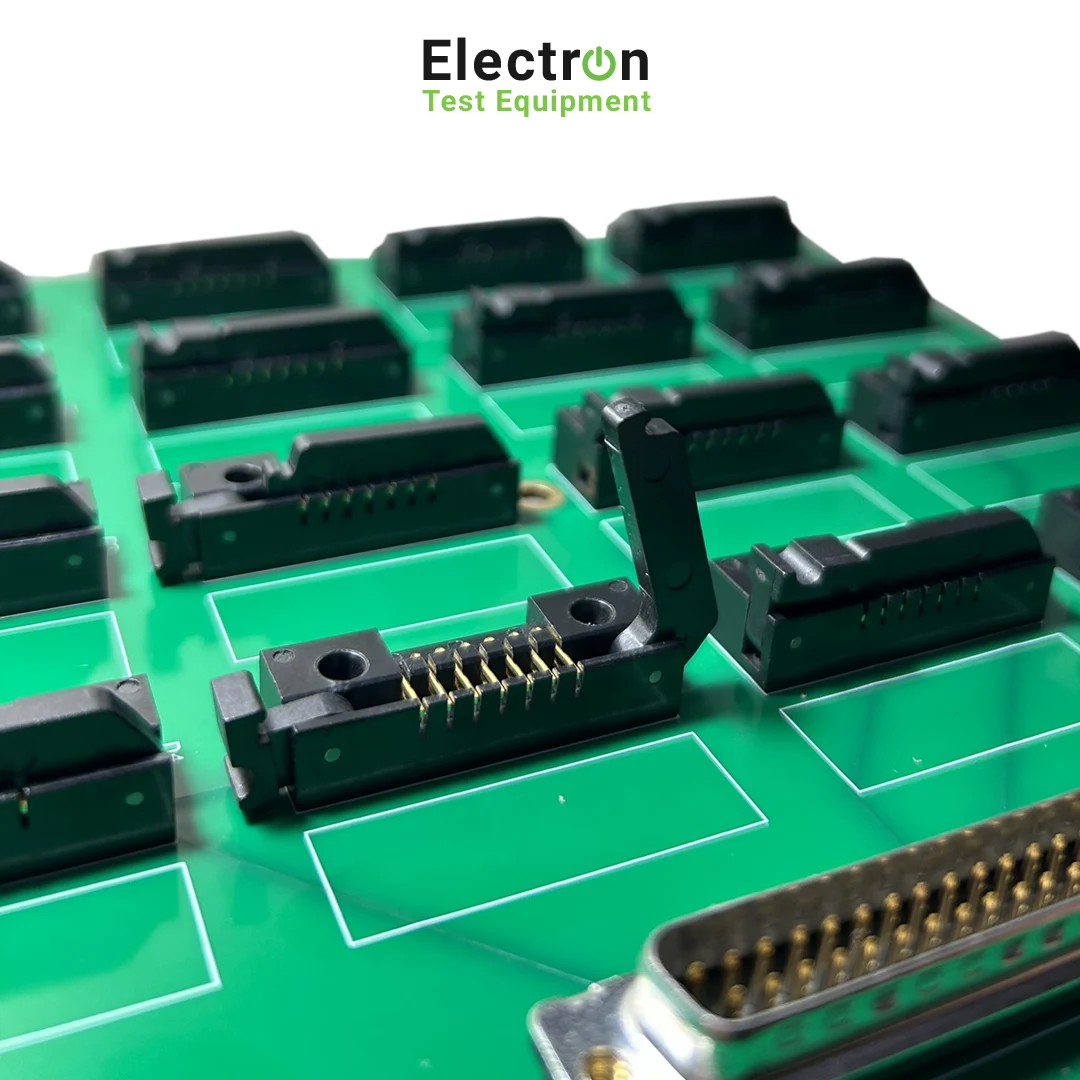

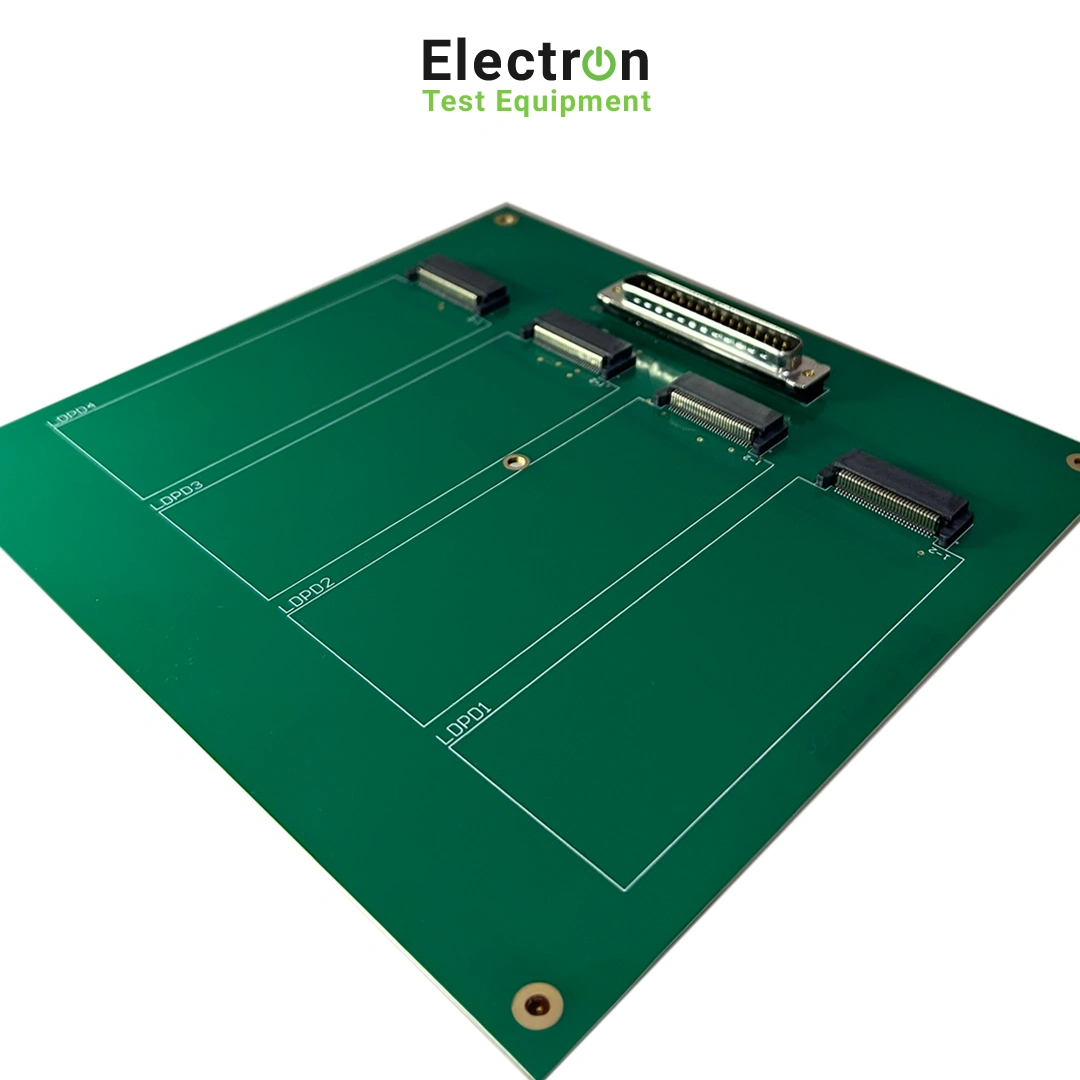

Compatibility with various wavelengths and laser diode packages, offering flexibility for different testing requirements. Simply swap the DUT board and you are ready to test.

Easy-to-use Software

Our user-friendly software interface and robust data management system facilitate easy operation and efficient data handling.

Environmental Testing Capabilities

The system is easily integrated with environmental test chambers, simulating various conditions such as humidity, vibration, and temperature extremes.

Case Study

for Global Semiconductor Manufacturer

Custom DUT Interface Boards

- Custom laser diode test fixture DUT (device under test) boards are built to meet your packaging & test specification

- Custom PRT- LASER system input and output interface board connections

- Custom interface control with third party environmental chambers

- Designed to operate up to 200°C

Resources

Laser Diode Datasheets, Case Studies, & Brochure

To access, please provide your:

The light current and voltage are key factors in determining the optical output power of a laser diode. A significant voltage drop can negatively affect the output power and reduce the overall optical output efficiency.

Our laser diode testing systems come with advanced software test configurations. You can customize settings that meet various organization test standards such as the Telcordia (Bellcore) GR-468-CORE, MIL-STD-883E, and Test Method 1016.

Reliability laser diode testing plays a critical role in ensuring the performance and longevity of laser diodes used in various applications. A comprehensive test system is used for optically tested diodes, where burn in testing and life tests are conducted to simulate long-term usage and stress. Through batch testing, manufacturers can identify any weaknesses in production runs, while qualification testing ensures that each laser diode meets the necessary standards for reliability. A robust reliability test system is essential for consistent reliability testing, offering accurate data that helps predict the expected lifespan and operational stability of each diode.

During laser diode qualification, key factors such as output power, voltage drop, and near field performance are evaluated to ensure high power operation and reliability. Accelerated aging is a cost-effective method to test laser diodes, verifying their durability while maintaining optimal optical power and ensuring they are optically tested for maximum efficiency. Semiconductor diodes are placed in an environmental chamber at a set temperature and current and is applied to the laser diodes at interval steps (LIV test sweep) and the intensity of the resulting emitted light and voltage is measured. The final laser diode LIV test results are displayed onto a graph which is known as an “LIV curve”. The following characterization can be determined based on the LIV measurement: Power vs. current ; Power vs. voltage ; Threshold current ; Series resistance ; Slope efficiency. With the rapid advancements in the electronics industry, reliability is a concern in every laser diode testing application. Laser diode life testing or accelerated aging is extremely important as part of qualification during product development as well as for batch testing throughout the production life of the laser. Also, high-temperature burn-in tests are used in laser diode manufacturing to filter out components prone to premature failure and ensure the remaining lot of laser diodes will meet the acceptable level of reliability based on the test standard used. Testing also ensures the diode delivers consistent output power under varying conditions. This qualification process is essential for achieving reliable laser performance while maintaining a low cost for high-volume production. By analyzing the resulting LIV curve, engineers can assess key characteristics like slope efficiency, which indicates how efficiently the diode converts electrical input into light. Proper testing also helps identify any issues with the diode element, reducing the risk of failures like catastrophic optical damage that could compromise the system's performance. Burn-in testing is often conducted to simulate real-world conditions and confirm the mean time to failure, ensuring long-term reliability. No, all semiconductors need to be packaged in order to mount them to the customer DUT (device under test) boards. Our dedicated support staff provides outstanding training and will help your team configure the software for your laser diode testing application. Depending on your requirements, the software can be customized to meet your semiconductor test requirements. When you choose an Electron Test Equipment product you not only get the most advanced semiconductor test equipment – you receive outstanding support and service.How does the RPT-LASER Works?

How Does The LIV Test System Works?

Why Use Accelerated Lifetime Testing & Burn-in for Laser Diodes?

How is Laser Diode Qualification Performed?

What is the Importance of Laser Diode Testing?

Does your equipment work with unpackaged components?

How does Electron Test Equipment provide training & support?

Laser Diode Testing

Quote Request

Need a custom laser diode reliability & burn-in test solution? Submit your requirements, and our application engineers will create a custom solution.

HEAD OFFICE

Electron Test Equipment Limited

5a Whytecliffe Road South, Purley, CR8 2AY, England

Phone: + 44 1293 904 001

E-mail:

moc.tsetnortcele@su-tcatnoc